THE GOAL

Odda Technology is a Norwegian-based global turnkey supplier of high-accuracy metal products for industrial use. It is a company drawing on a long history of industrial expertise. CLEVR is an emerging name in product lifecycle management (PLM) system integration. An innovative project saw the two companies partnering to establish an industry standard where manufacturers use 3D models as the basis for production.

Odda Technology had started to digitalise the process that took products with a low-production volume from design to being ready for manufacturing start-up. This project was supported by Innovation Norway – a state-owned company encouraging entrepreneurship – with partners being large engineering companies that design equipment and components for the oil and gas industry.

Odda Technology needed support in streamlining the process from customer drawing board to initiating production in a way that maintained high quality levels. CLEVR – a low-code and no-code solutions expert – provided the expertise in this digital transformation.

THE APPROACH

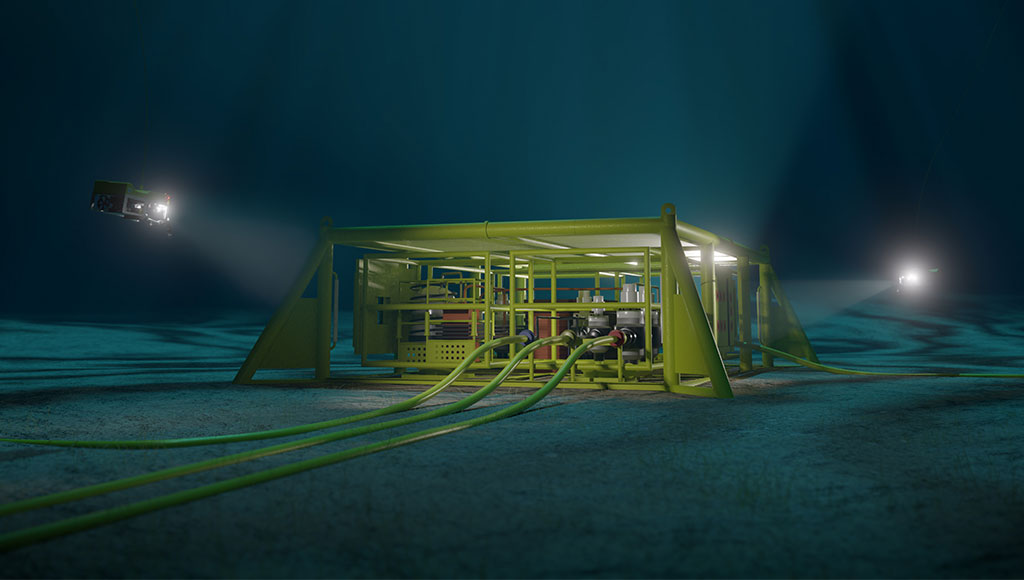

Odda Technology faced the challenge that low-cost countries usually beat Norway on hourly rates for personnel. It is one of the reasons why the Norwegian industry is not a big player in mass production. It does, however, lead the way in producing parts and components in smaller series where very high demands are placed on quality, accuracy and precision – for example the production of coupling components for the subsea industry. This incorporates deliveries to the offshore industry, which has made Norway a world leader in underwater technology.

Odda Technology produces numerous products that are roughly the same, but unlike regular series production, each product is uniquely tailored to suit a specific facility on the seabed. This type of production is often referred to as one-piece flow, or continuous flow. Each product must be designed, calculated, described and documented in meticulous detail before it can be produced. There was a need to streamline this process.

The existing processes were highly labour-intensive and required a lot of specialist knowledge. But there was a desire to develop this expertise further to ensure it contributes to even greater improvements in efficiency and create a fully automated setup procedure. Achieving it paves the way for developing a new standard for the digital exchange of component information – from design to finished parts.

CLEVR also supported this digital transformation project through technology solutions and highly specialised consulting services.

THE RESULTS

Large, future-focused engineering companies that design equipment and components for the oil and gas industry recognised the value of this project and were keen to be involved.

The project has the potential to give the industrial sector a genuine competitive edge. Norway is already a world leader in the development and production of advanced industrial parts. The next big step in industrial systems manufacturing is the digitalisation of this type of process. It will help the broader industry work smarter and more efficiently, and stay ahead in terms of competence and expertise. The project will also bring synergies in other industries and is considered to have global scalability.

CUSTOMER QUOTE

“This project will allow us to analyse what is needed for customers to deliver fully digital packages that we can import so that our set-up procedure is fully automated”

Ingvald Torblå, CEO, Odda Technology